Generator Load Sensor Experience at Location Solutions

Generator Load Sensor Experience at Location Solutions

As projects go, large numbers of machinery get continuously transported between locations along with generators, too. With that, comes a great deal of expenses on fuel and operational cost.

Sometimes, these expenses are redundant, yet project managers realize that they could’ve cut their costs way after the project has ended and after the assets ( aka generators) have been dispatched and the resources have been consumed.

At Location Solutions, we have just the right solution to bring down some of these spendings to a minimum through a simple yet effective load sensor solution connected to a tracking device.

The Load Sensor provided by Location Solutions is a small unit that gets connected to the GPS Tracker attached to diesel generators on-site.

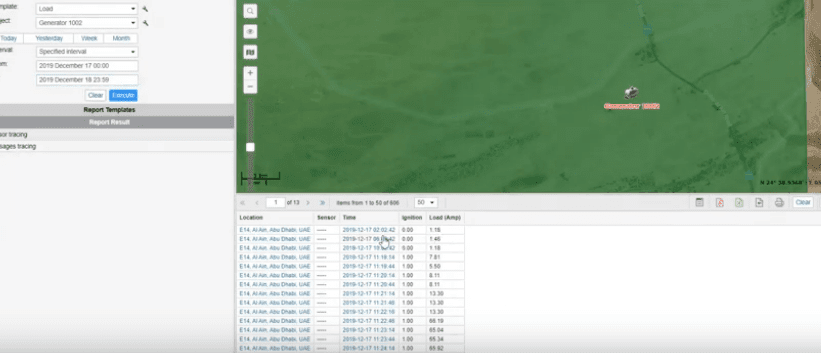

Load sensor solution gives a range of KPIs, which allow to define the type of asset utilization, maximize its efficiency or replace the unit with one that reflects the capacity required for the project.

For example, sometimes large-capacity generators are used for small purposes – and if so, this data will be reflected on the graph with the sensors’ data. Once the KPIs are established and errors identified, these generators can be redistributed, returned, or orderly handled leading to cost optimization and better usage of resources.

The system generates automated reports that are shared with Plant Managers & stakeholders to identify the usage and abuse of the generators and the more informed decision-making.