Safe Mix

Client : Safe Mix

Safemix keeps Concrete Pumps in check with Location Solutions

Case Studies : Safe Mix

The Cause

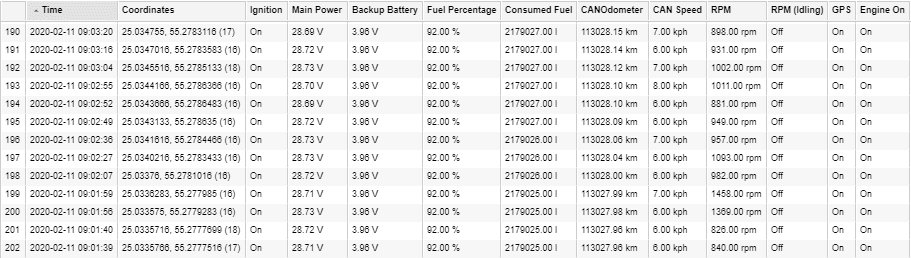

Because the experience provided entails more than just regular GPS tracking and reading, our service proved its significance when we were able to measure the actual idle time for the concrete pump.

Concrete pumps’ engines usually stay on during pumping yet don’t move location; this means that the engine is still running usefully but not moving geographically. Usually in other vehicles, measuring whether or not engine time is being wasted is simply through whether or not the vehicle is moving. However, in this scenario, Location Solutions yet again uses advanced technology to its advantage as we’ve used a formula that would calculate the idling time among other parameters of vehicles through their RPM rather than a geographic spot.

So how do we know if the driver is misusing his operating time?

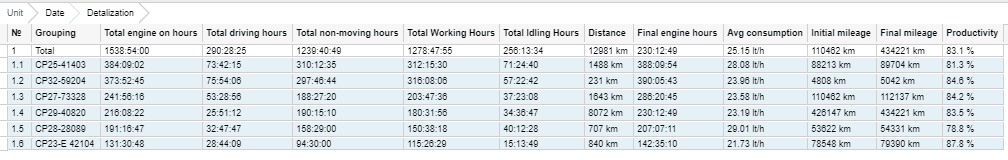

Through Engine/ RPM Idling, Fuel Cost and Operational Costs decrease as well as Maintenance costs (for, on average, maintenance is required for engines every 250 hours.)

The accuracy of the system is very satisfactory as well, as all parameters get captured through the most advanced CAN bus reader, resulting in accurate productivity levels and therefore best recommendations.

Through the LS2 experience, Safemix didn’t just monitor Idling Time, but also Fuel, Speed, and Odometer Readings making it one of the most comprehensive and reliable experiences one can get in the industry.

Reports include:

It calculates the actual utilization of a pump based on the RPM data.

In one report, the observer can relate the number of the actual idling hours to the engine hours and eventually get the accurate productivity reading

Fuel Consumption, Actual Odometer, Actual Speed, Engine hours, etc…